Type in a search word

What are you looking for

Record results for “VMG Technics”: 140 innovations created in a year, reaching €33 million in revenue

The company “VMG Technics” which develops industrial robotics and artificial intelligence solutions, achieved a turnover of €33 million in 2023 and implemented 140 innovation-based projects. This year, the company plans to export its solutions to Scandinavia, Western Europe, North America, and Canada.

According to Mantas Leknius, the CEO of “VMG Technics”, approximately 40% of the services and products developed last year were sold, while the remaining portion was allocated to other VMG group companies.

“In recent years, we have successfully universalized our products and adapted them to other industries. Not all of our production was intended for foreign markets; some solutions were developed exclusively for Lithuanian companies. We are observing that strong industrial nations are increasingly investing in industrial robotics and automation, making the implementation of these technologies in our country’s manufacturing sector crucial for enhancing its competitiveness,” says M. Leknius.

AI and robots: inseparable from industry’s future

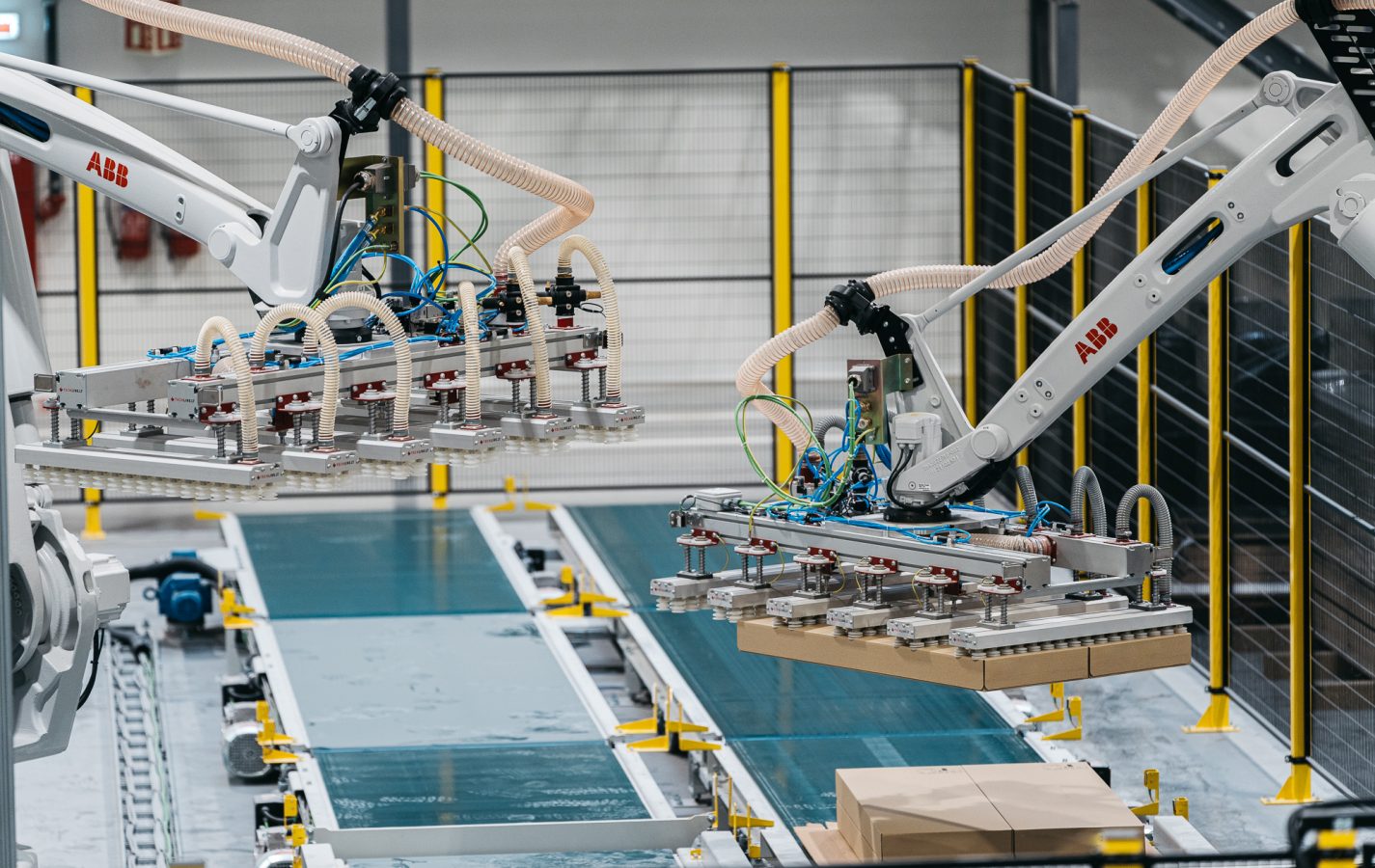

Some of the most important technologies “VMG Technics” developed last year for companies operating in Lithuania include quality inspection systems for packs and wrapping systems for furniture packaging pallets. These technologies utilize robots and artificial intelligence, which have become integral to the automation of industrial processes. These solutions will help companies increase productivity, reduce costs, and minimize the need for human intervention in processes, thereby reducing the likelihood of errors.

Another technology developed and implemented last year is designed to detect and eliminate various defects in parts. The system uses 22 high-resolution cameras to capture images from all sides of the product. Artificial intelligence and machine learning algorithms automatically detect discrepancies and identify the type of part. Upon detecting a defect, the system sends a signal to the rejection table, where defective parts are removed.

The company also manufactures complex equipment and metal structures, producing 300 tons of these in 2023.

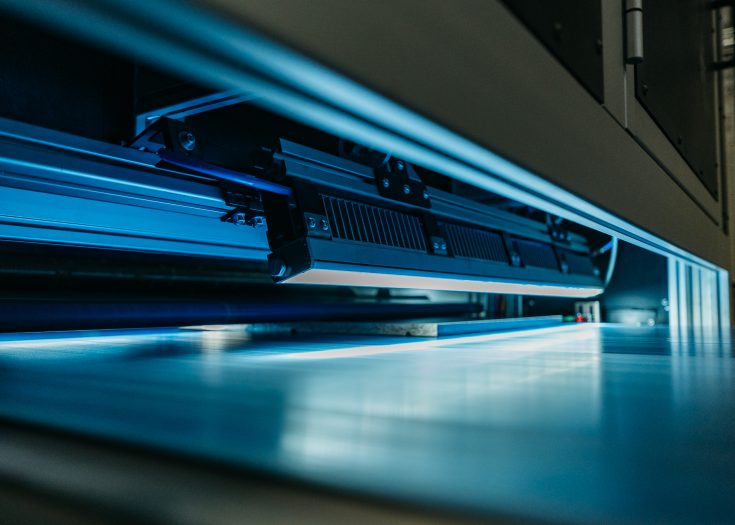

“For one company focused on renewable energy production, we developed a surface processing machine for composite materials, capable of not only cutting the material in different directions but also drilling holes at the intersections of the cuts. The machine operates with both saws and drills, allowing for extremely high productivity,” shares M. Leknius.

The company’s capabilities were significantly expanded in the second half of 2023 with the launch of operations at the not-yet-officially-opened but already functional industrial innovation park “VMG Technics R&D Park”, considered the largest in the Baltic region. The innovation park, which has been designated as a strategic project by the state, is set to be officially opened in September of this year.

“Last year, we received €32 million in investments, more than a third of which was allocated for the purchase of various equipment. Therefore, we are now planning for even greater volumes. We estimate that this year, “VMG Technics” should exceed the revenue achieved in 2023 by 30%,” says M. Leknius.